Before learning how to use a spot welder, I had to learn how to cut sheet metal.

I used a shear to try to achieve a smooth, clean cut. I held the shear steadily and used the table for leverage to cut the sheet metal.

To use the spot welder I needed sheet metal to weld.

I cut along the lines on the sheet metal using the shear, roll, and brake machine.

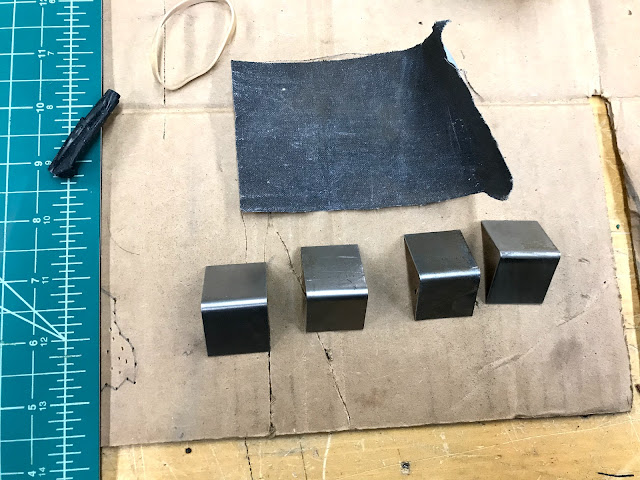

Before spot welding, I used sandpaper to clean the outside of the sheet metal. Rust and stains yield weaker welds.

A fellow classmate demonstrated how to use a spot welder. To use a spot welder you must wear safety goggles and leather gloves. The machine sparks when it is activated.

My classmates and I pulled apart the welded pieces of sheet metal. We did this to test the strength of each weld. As the heating period reached seven seconds, the weld grew stronger.

I continued welding more pieces of sheet metal and increased the heating period. However, heating the metal for too long only burnt the metal. I was told by my instructor, Mr. Grosinger, that nine seconds was way too long and past the machine's limitations.

The weld grew stronger. I was unable to find the point in time (length of heating period) at which the sheet metal joints begin to weaken.

No comments:

Post a Comment