I used two different files to sand the edges of the metal leg. The first file was more coarse than the second. I used sandpaper to refine the edges.

I used the break, shear, and roll machine to bend the metal. The angle of the bend was approximately 90 degrees.

I used a body hammer to flatten the upper end of the stool leg. I attempted to straighten out the end of the leg so that it could be attached to the chair.

I used an old stool leg as a template. I continued replicating the shape of the old leg by hammering the sheet metal on different surfaces.

I hammered the lower end of the stool leg. I hammered the metal on different surfaces to duplicate the original design.

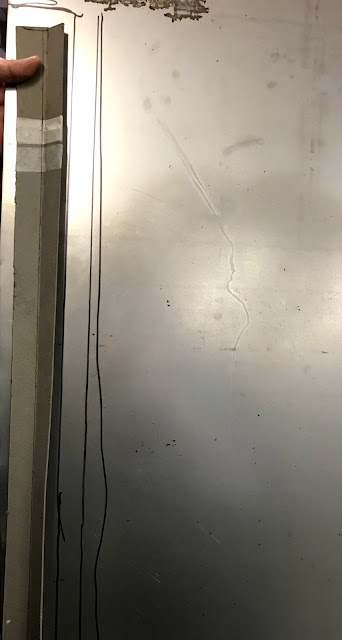

Before attaching the leg, I used sandpaper to remove the rust surrounding the corner of the stool. I used coarse sand paper to remove and flatten large metal bumps.

I used files and sandpaper to flatten and sand down the corner of the footrest. Sanding down the corner made welding the replacement leg easier.

I used clamps to hold the leg in place. I double checked my initial measurements and made sure each leg was the same length.

I sanded the bottom of the stool and removed a large layer of rust.

Although the new stool leg was now attached, the thinner material meant that it was still weak.

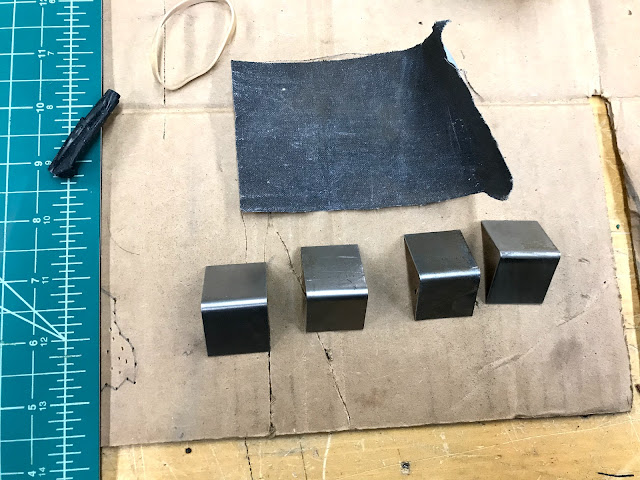

I used cardboard models to test out different ideas. I brainstormed different methods of making the stool leg stronger.